Second Hand High Speed Packing Box Corrugated Carton Cardboard

Production Line

Technical Parameters

* Operation style of base paper stand: Electrically mechanical type

* Dia. of clip paper: Φ350mm - Φ1400mm

* Max. weight of one side: 2000kg

* Working pressure of air supply: 0.6-0.9 MPa

* Total power: 5.2kw

Structural Features

A. The symmetric structure can be installed with two bundles of

base paper at the same time used to change papers without halt.

B. This machine adopts the electrical driver to finish lifting up

or down, clamping, loosening and centering the base paper.

C. This machine adopts the pneumatic tension controller to adjust

the tensile force of base paper.

D. The head of clip paper adopts expansion style.

E. The tension control adopts pneumatic braking, which can also be

on-line control together with Paper Splicer.

Max. working width

1600mm

Max working steam pressure:

1.0-1.3Mpa

Steam temperature

160—210 centigrade

Power requirements:

380V, 50Hz

Diameter of heating roller

400mm

2.High Speed Fingerless Type Single Facer

Specification:

Max. machine speed | 80m/min |

Economic speed | 60m/min |

Max. working width | 1600mm |

Max working steam pressure: | 1.0-1.3Mpa |

Steam temperature | 160—210 centigrade |

Power requirements: | 380V, 50Hz |

Diameter of corrugated roller | 268mm |

Diameter of Press roller . | 268mm. |

Diameter of preheater roller | 280mm |

Diameter of Glue roller | 215mm |

Diameter of doctor roller | 105mm |

*Design speed: 80m/min.

*Corrugated rollers made of 48CrMo alloy steel, with heat treatment

for hardness HRC58-60, surface plated with chrome treatment.

*corrugating roller: Dia.280mm with a drum.

*Press roller: Dia.320mm. with drum.

* Vacuum suction Fingerless design provides perfect flute formation

in high speed manufacturing.

* Gimbal driver system. Individual immersion oil gear type drive

box, separating dynamic vibrations improve running stability, easy

and fast for maintenance

*Gluing roller: surface is embossed with netting design and chrome

plated.

*Adjustment of upper corrugated roller, pressure roller and glue

roller controlled by pneumatic system.

*With preheating and preconditioning rollers.

3.Overhead Bridge

Vacuum tension control ,Electric paper way control.

4.Single ply Gluing Machine

For Three ply Line With PLC & Auto Adjust Glue

Max. machine speed | 120m/min --150m/min |

Economic speed | 100m/min--120m/min |

Max. working width | 1400mm |

Max working steam pressure: | 1.0-1.3Mpa |

Steam temperature | 160—210 centigrade |

Power requirements: | 380V, 50Hz |

Diameter of glue roller | 242mm |

Diameter fo preheater roller | 300mm |

Diameter of doctor roller | 125mm |

1.High precision engraved applicator roll ensure uniform glue

application and less glue consumption.

2.Pressing roller type with high manufacture efficiency, pneumatic

control, easy and fast to operate.

3.Auto-circulating glue feeding system is applied to avoid glue

depositing.

4.Driving source is from double facer,it can adopt PLC auto

adjusting gluing system.

5.The self-preheating device speeds up glue gelling and create a

stronger glue .

5.Double Facer

Specification:

| Max. machine speed | 100m/min |

| Economic speed | 80m/min |

| Max. working width | 1600mm |

| Max working steam pressure: | 1.0-1.3Mpa |

| Steam temperature | 160—210 centigrade |

| Power requirements: | 380V, 50Hz |

| Width of heating palte | 600mm |

| Number of heating palte | 9pcs |

| Diameter of press roller | 60mm |

| Thickness of belt | 10mm |

*Heating plate:1700mm(L)×600mm(W)×120mm(H)×9pcs

Made of steel plate, polish plate.

*Steam pipe for heating plate, divided into 4 sectionsn

respectively.

*The heating temperature for each section can be showed .

*For adjusting the tension of upper cotton belt with:

one set pneumatic adjusting device.and one set manual adjusting

device; Air cylinder:dia.160mmx250mm stroke.

*For adjusting the tension of lower cotton belt with: one set

manual adjusting device.

*For guiding the upper cotton belt with: one set manual adjusting

device.

DRIVE ROLL STAND 1 SET

*Upper roller: Dia.500mm×1700mm(L)

wrapped by wear-resisting asbestos cloth.dr

*Lower roller: Dia.440mm×1700mm(L)

wrapped by wear-resisting asbestos cloth.

*Cotton belt pinch roller: Dia.320mm×1500mm(L)×2pcs

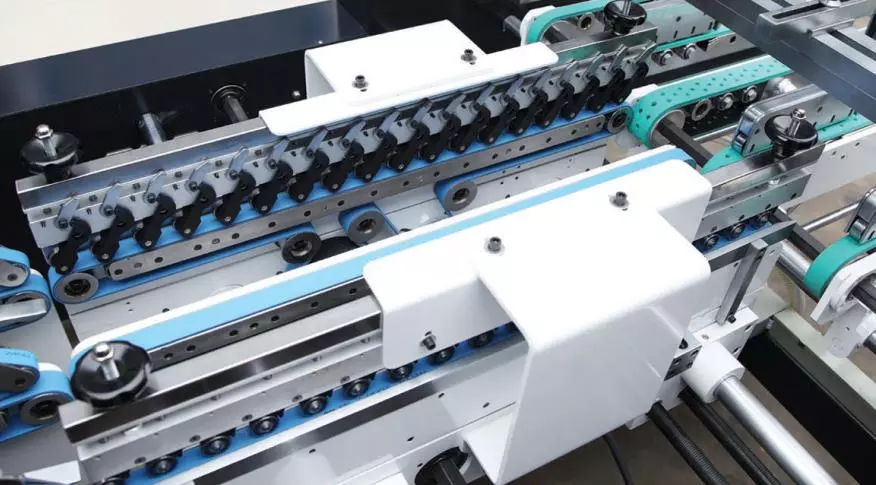

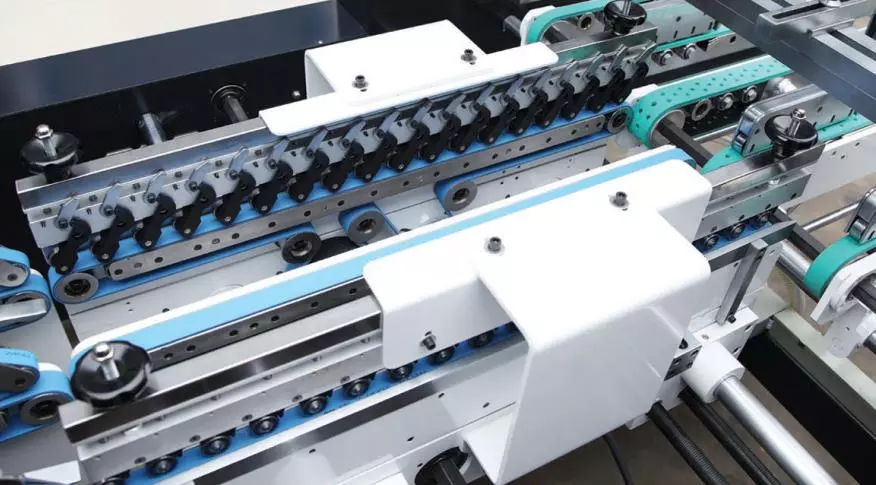

6.Thin Blade Slitter Scorer

Specifications:

| Width | 1600mm |

| Cutting lenth | 500—9999mm |

| Order keeping | 999orders |

| Cutting precision | ±1mm |

| Power | 11kw |

| Knive roller diameter | 190mm |

| Max.production speed | 100m/min |

Machine Introduction:

-Special structure type, high quality wallboard and seat, reliable

and slinky.

-With watch-window on two sides wallboard, easy for see in

manufacturing and maintenance.

-Driving part adopts hermetic lubricate, make sure high precision,

high stability.

-Adopts high precision and rigidity lapping gear, suit for high

speed, oil felt lubrication prolong work-life. Ensure cutting blade

accuracy meshing, carton sheets without raw edges.

-High precision cutting shaft and cutting seat, reliable and

slinky.

-Special structure design in changing blade, easy and fast to

change blade.

-Whole system design C.E standard strictly, pass industry computer

test strictly, ensure high quality, long work life and stability.

-Driving part adopts AC servo drive, drive system made in Germany,

high quality and swift.

-Use in frequency electric system, save electric and could overcome

power unstable.

-The system had automatic check function, and could prevent

equipment mangled by operate out of the rules or cursoriness

operation.

-Computer could automatic adjust cutting acceleration according

paperboard size and manufacture speed, automatic follow

paperboard’s speed, ensure in-phase.

- Computer could storage 999 different cutting orders, and could in

order or priority choose cutting order.

-Equip with touch screen display and PLC control system.